Digital infrastructure is transforming the future of construction

Published on: October 17, 2025

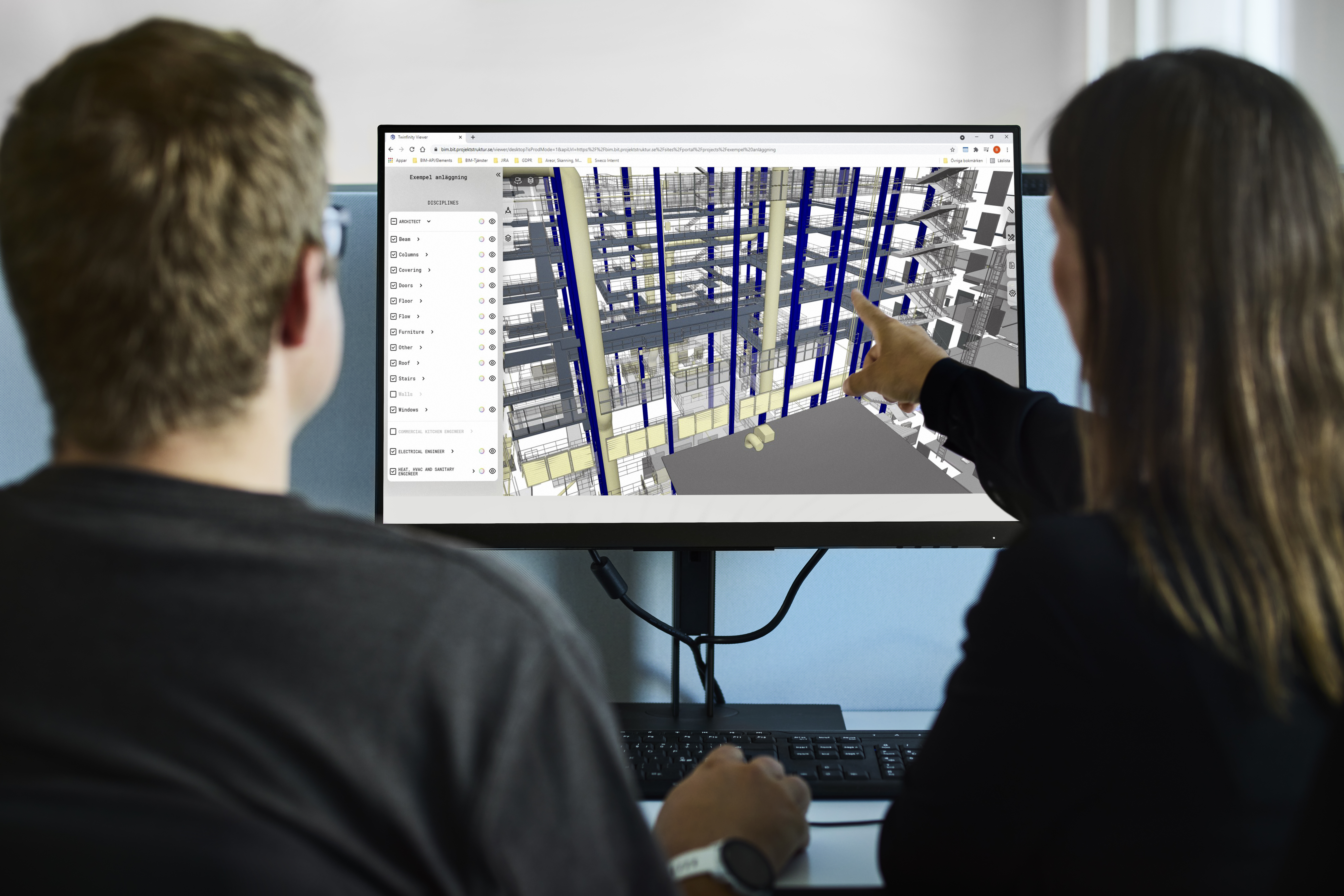

Digitalisation is redefining how infrastructure is designed, delivered and maintained. Traditional projects relied heavily on paper drawings, separate teams and physical models that could only show part of the picture. Now, engineers and architects work within shared digital environments where information is updated in real time. Building Information Modelling (BIM), digital twins and carbon footprint simulations allow projects to be tested virtually, refined before construction and monitored long after completion.

These advances are not just about saving time or money. They enable infrastructure to be more resilient, sustainable and adaptable. By simulating how assets will behave in different scenarios, project teams can plan for the future with greater confidence. By integrating environmental data into models, they can make choices that directly reduce emissions and resource use. Digitalisation is becoming an essential foundation for modern infrastructure.

Sweco’s offering in digital infrastructure

Sweco has been at the forefront of this shift, integrating digital methods into projects across Europe. The company combines engineering expertise with advanced digital tools to cut risks, improve coordination and deliver sustainable outcomes. Whether it is a transport depot, a heritage redevelopment, a critical bridge or a cross-border megaproject, Sweco uses digitalisation to turn complexity into clarity and to ensure projects are delivered to the highest standards.

Designing transport with a lighter footprint

The Ruskeasuo tram and bus depot in Helsinki sets a new benchmark for sustainable infrastructure. The project took a proactive approach by embedding environmental goals at the very start. Instead of waiting until construction was complete to calculate emissions, the design team used data-driven carbon footprint modelling from day one.

This process made it possible to test different options for structures, materials and energy systems in a digital environment. Each decision could be compared against its impact on overall carbon emissions. It meant that low-carbon alternatives could be chosen without compromising functionality. The depot was not only planned to meet the needs of a busy transport hub, but also to operate in a way that reduces its long-term environmental impact.

By applying this level of precision, the Ruskeasuo project demonstrates how digitalisation can directly support climate goals. Carbon is no longer an afterthought but an integral part of the design process. Sweco played a key role in leading the modelling work and guiding the design solutions to ensure the depot was both functional and environmentally responsible.

Digital tools for heritage transformation

Brussels’ Gare Maritime has undergone one of the most ambitious redevelopments in Europe. Once a vast and neglected freight station, it has been transformed into a vibrant mixed-use destination that combines offices, shops and public spaces within one of the largest timber structures ever built on the continent.

Working with a historic site presented major challenges. The existing structures had to be preserved while new sustainable materials were introduced at scale. BIM was central to making this possible. The digital model served as a shared platform for architects, engineers and contractors, allowing them to coordinate seamlessly and identify clashes before they became costly issues on site.

The digital model also supported the innovative use of timber. By ensuring precision in design and fabrication, waste was reduced and construction became more efficient. Beyond the building phase, the BIM model continues to support facility management by providing accurate data on building systems and performance.

The Gare Maritime redevelopment shows that heritage projects can embrace modern sustainability standards without losing their historic character. Sweco contributed engineering expertise and coordinated the BIM process, helping to bridge the gap between conservation and cutting-edge design.

A Digital Twin for the Heinenoord Tunnel

The Heinenoord Tunnel on the A29 is a vital transport link, carrying tens of thousands of vehicles every day. To support its renovation and minimise disruption, Sweco developed a digital twin of the tunnel. This virtual model integrates data from the tunnel’s control and monitoring systems, enabling engineers to test installations and simulate operational scenarios before work begins in the physical environment.

The digital twin was built using an integrated BIM approach and 3D models, which were used to create a Virtual Reality environment. This allowed realistic testing of the tunnel’s technical systems, helping identify risks early. It also provided a safe space for traffic operators to train for emergency situations without affecting live traffic.

Sustainability was central to the project. The digital twin enabled evaluation of energy use, material choices and CO₂ emissions, helping implement optimised environmentally responsible solutions. Renovation measures included new LED lighting, energy-efficient systems and material reuse wherever possible.

By combining scenario testing, operator training and sustainability analysis, Sweco’s digital twin helped the team manage risks proactively, reduce costs and improve efficiency. The approach ensured the Heinenoord Tunnel renovation would be safer, more reliable and environmentally sustainable, demonstrating how digital infrastructure tools can transform complex transport projects.

Digitalisation at mega-scale

The Fehmarnbelt tunnel between Denmark and Germany represents one of the largest and most complex infrastructure projects in Europe. Stretching 18 kilometres under the Baltic Sea, the immersed tunnel will carry both road and rail traffic, reducing travel times dramatically and strengthening cross-border connections.

The scale of the project requires unprecedented precision. Each of the tunnel’s massive prefabricated sections must be designed, manufactured and integrated with absolute accuracy. Any misalignment could cause delays or compromise safety. Digitalisation and BIM make this level of coordination possible by providing a shared environment where engineers and contractors across borders can work together in real time.

Potential problems are identified in the model long before they appear on site, saving time and resources. The digital approach also enhances safety during construction and ensures that sustainability goals are met by optimising the use of materials. Looking beyond completion, the tunnel’s digital backbone will support monitoring systems, safety management and maintenance for decades to come.

The Fehmarnbelt project demonstrates how digitalisation can scale up to meet the demands of megaprojects, creating infrastructure that is not only functional but also resilient and efficient. Sweco is part of the international engineering team using BIM and advanced digital tools to manage complexity and deliver this landmark tunnel.