Industry’s new era: Cutting emissions by embracing the circular economy

Published on: April 12, 2024

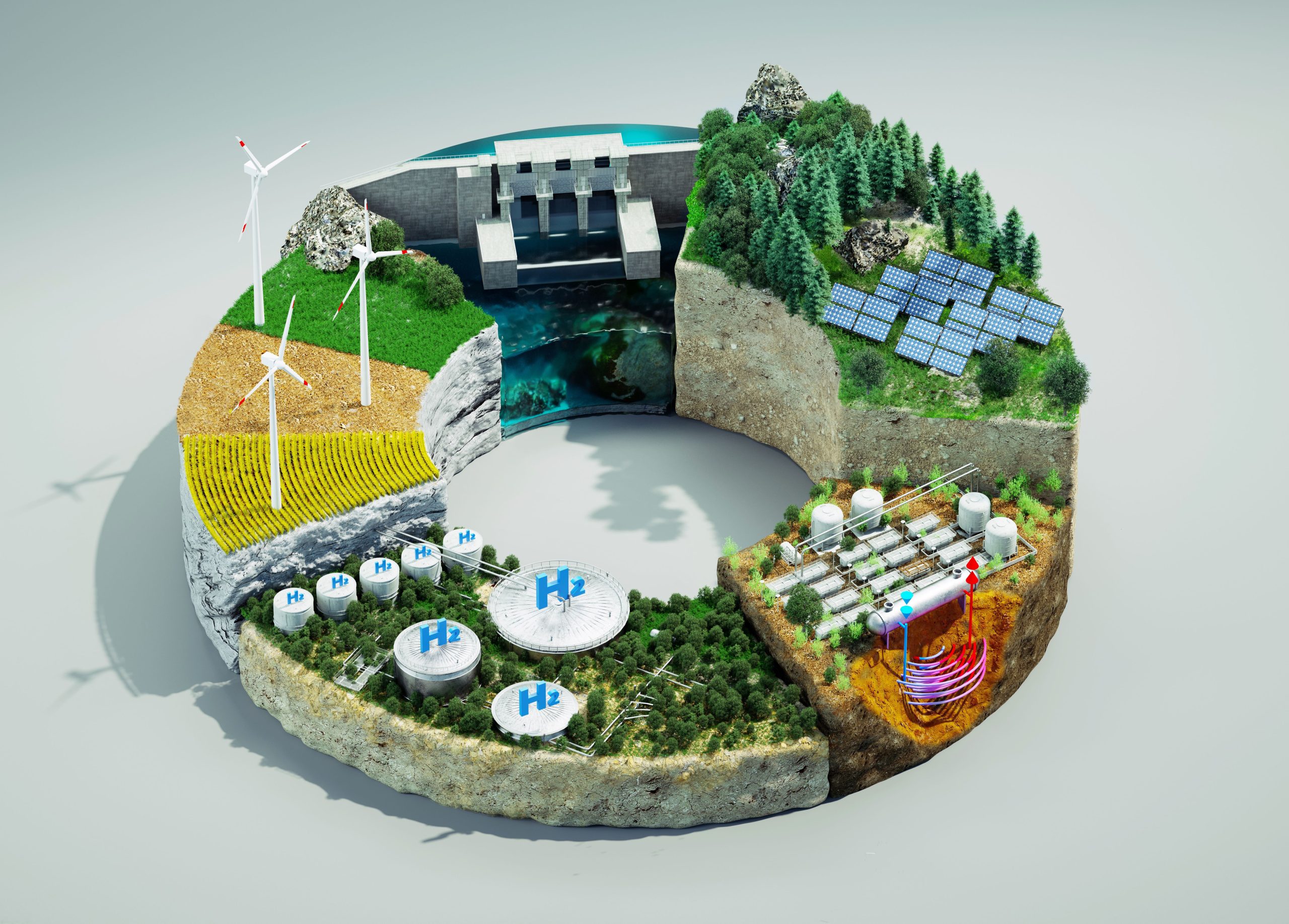

The secret to reducing emissions and energy consumption lies in the art of recirculation—transforming what we once discarded into the building blocks of tomorrow.

With steel, cement, aluminium and plastics accounting for more than 60 per cent of industry-related CO2 emissions, the circular approach offers a significant promise, potentially slashing these emissions by 56 per cent come 2050.

“Circular economy is crucial when enhancing green transition in society,” says Tomas Norrena, Development Manager, Circular Economy, at Sweco Finland. “Circularity enables a new way of thinking as linear economy needs to be left behind. The change needs to happen in, for example, the manufacturing sector and naturally companies need to react, but consumers also need to reset their consumption patterns as we have been overconsuming for too long.”

Photo Credit: R. Koirikivi / Studio P.S.V.

Rethinking design for a circular future

The potential becomes even more clear when you consider the fact that most of the materials that the EU economy will need by mid-century have already been produced — 75 per cent of steel, 50 per cent of aluminium and 56 per cent of plastics.

But the degree of circularity varies greatly depending on the material. Recycling is already happening for the vast majority of all steel production, with a recycling rate of 80-85 per cent. Recycling in the plastics sector presents a number of challenges due to the variety of plastic types and their widespread distribution.

Bridging this gap requires a shift in the paradigm of product design. Whether dealing with the complexities of plastic or the relative straightforwardness of steel, the focus must be on creating products that are born to live multiple lives.

Designing products with circularity in mind is key, encompassing both industrial and consumer items. This approach involves evaluating a product’s impact beyond its initial use phase, with the anticipation that it will be resold, remanufactured or repaired to prolong its lifespan. Designing for circularity necessitates the adoption of fundamental design principles and a deeper understanding of material utilisation.

“Adapting needs to occur in the early phase of the process. We need to be aware of the reuse and recycling potential when designing new products to the market,” Norrena says. “Companies need to also remain open-minded for new partnerships and cooperation possibilities, as well as reconsider what is done within the company and what can be outsourced in order to improve their efficiency.”

Unlocking new markets with circular strategies

Industrial symbiosis can be created by using waste produced by one process as a resource for another, serving as a key component of the circular economy. This strategy enhances industrial circularity by fostering the exchange of information and byproducts, thereby generating both economic and environmental benefits within a collaborative network of industry participants.

“Forming industrial symbiosis can create more resilient supply chains, especially in the current market situation,” Norrena says. “It can also create new export opportunities. In addition to this, forming industrial symbiosis could improve cost efficiency of one’s actions.”

Circularity also provides a number of other business opportunities for the industrial sector.

“For instance, traditional products can become services by utilising sharing platforms. In addition to this, new feedstock basis, which is based on recycled material and industrial side streams, can support the competitiveness of pioneer companies.”

Building on this notion, Norrena emphasises that the scope of our efforts must broaden.

“Focusing only on recycling isn’t sufficient action anymore — we need to adapt circularity to all our actions.”

Sweco’s services for the circular economy

Sweco’s services for the circular economy cover the project’s entire lifecycle, including different planning phases. We customize our services on a case-by-case basis to meet the client’s needs. We also make use of our experience in the implementation phases of industrial projects to support the early development efforts of various projects.

Sweco’s services cover circular economy projects from the design phase to the demolition and reuse of the building or industrial plant.